Održavanje

Citerm | Heating Systems

Održavanje

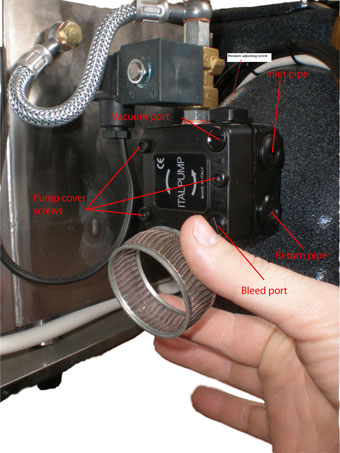

- Unscrew pump cover screws

- Clean metal strainer (see picture)

- Be careful not to damage gasket

Cleaning oil line

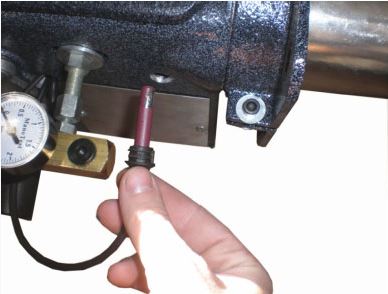

- Unscrew vacuum port screw

- Blow in with compressed air gun

- You will hear bubbles in the storage tank

- Screw back vacuum port screw

- Unscrew bleed port

- Turn the burner on

- When oil arrive, close bleed port.

Supply lines

Read this section carefully before installing any supply lines. Since a suction line leak is nearly impossible to find, take your time to assure all connections are leak-free during installation. Always use liquid Teflon to seal all fittings on the oil lines.

That is only way to prevent false air coming into pump. Always use clamps to tight oil pipes to fittings.

Always use liquid Teflon to seal all fittings on the oil lines. That is only way to prevent false air coming into pump.

Always use clamps to tight oil pipes to fittings.

Photo-cell

Photo-cell (flame sensor) must be cleaned every 30 days. If the photo-cell is dirty, burner will start flame and after 4 sec.

Control box will show malfunction (red light will appear) Be careful to turn the photo cell to “see” the flame. (see picture)

Citerm | Heating Systems

Burner pump cleaning

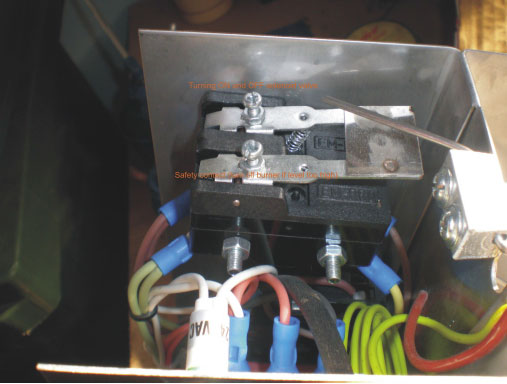

Double switch

Be careful when adjusting double switch! Normal fuel level is 50mm from the top of the heater. Safety contact must trigger if level raise to 25mm from the top of the heater.

Boiler

Ceramic fibre – necessary for all burners when used with steel boilers with large combustion chamber or cast-iron boilers with a vertical rear panel in the combustion chamber. Ceramic fibre will prevent making deposits of unburned oil at the bottom of the boiler.

Drain tap

It is necessary to open drain tap To release settled water.

Depending on the quality of the oil used, we recommend the following maintenance intervals: Monthly:

- Clean the filter in the supply tank or the unit tank and strainer on the floating suction unit

- Check the oil level in the supply tank to be shore that enough fuel is available.

- Remove and clean the feed pump filter • Remove sludge and residual water from the supply tank or unit tank

- The quantity can be determined by using water indication paste and a gauging rod • Clean the photocell

- Clean the ignition electrodes and flame ring and blow out the nozzle with compressed air, check the spacing between the ignition electrodes (refer to checking dimensions for ignition electrodes page 14)

- The electrode porcelain insulators must be free from carbon, oil, dirt, cracks. Otherwise, short circuiting could cause ignition problems.

- Check boiler, if it is dirty, clean it.

Annually (before or after the heating period):

- Carry out monthly maintenance as described

- Clean the heating cartridges in the burner tank • Clean the ignition electrodes and baffle plate, blow out the nozzle with compressed air and check the spacing between the ignition electrodes

- Clean the burner tank, supply tank and unit tank thoroughly.

- Clean the boiler and chimney.