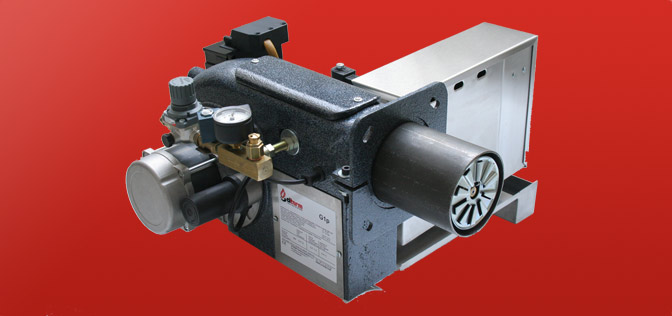

Termogeni gorionici na staro ulje - GP Serija

Citerm | Heating Systems

Uvod

CITERM gorionici su dizajnirani da sagorevaju: Biljno ulje, iskorišćeno ulje kartera, hidraulička i transmisiona ulja, Ekstra laka gorivna ulja, laka i srednja gorivna ulja, ostale zapaljive tečnosti…

Patentirana tehnologija obezbeđuje sagorevanje otpadna ulja bez obzira na njihovu viskoznost ili tačku zapaljivosti. Predkomora zagreva sva ulja do temperature gde postižu istu viskonzonst. Ulje se raspršuje komprimovanim vazduhom pod relativno niskim pritiskom. To omogućava upotrebu večih dizni koje se ne zapušujue čak ni pri korišćenju đubrivnog ili polutečnog ulja.

Šta je nophodno za korišćenje gorionika?

- Bojler ili termogen

- Komprimovani vazduh (pritisak u rasponu 2 – 15 bara)

- Rezervoar

- Strujni napon: 230~V; 1280W; ( 6 Amp. )

Citerm GP serija gorionika namenjena je industrijskoj ili komercijalnoj upotrebi. Oni oslikavaju naše dugogodišnje iskustvo i posvećenost u razvoju ‘zelenih’, efikasnih i vrlo kvalitetnih proizvoda u ovoj oblasti. Postigli smo visoke standarde i pri tome Vam ponudili vrlo pristupačan proizvod.

Gorink bi trebao instalirati iskusni serviser sa iskustvom u ovoj oblasti.

Ako obratite pažnju na sledeće detalje postaćete član širokog kruga zadovoljnih korisnika: CITERM MULTIFUEL BURNERS.

CITERM gorionici su dizajnirani za sledeća goriva: EL fuel oil, bio-dizel, domaće ulje, organsko ulje, otpadno ulje kao i za kombinacije svih navedenih.

How it works?

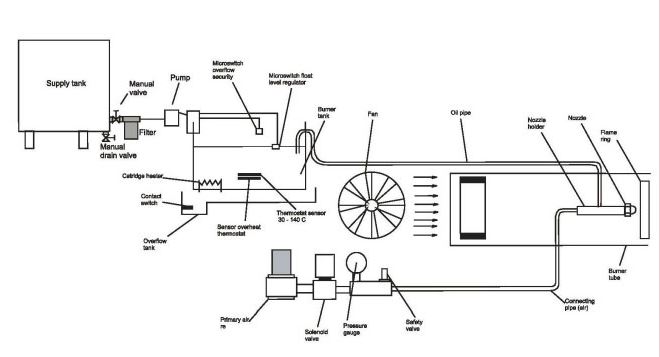

Fuel is pulled from the storage tank by pump into burner tank. A floating switch regulates the level in the burner tank. An additional floating micro switch funcions sa a limit switch which indicates „malfuncion“ in case of overfiling. A contact switch stips the burner in case of overflow in the tank. A thermostat regulates the oil temperature in the burner tankand swiches on the burner automatically as soon as the regulatedtemperature is reached.

An additional overheat thermostat prevents overheating with malfunctioning. Then the burner control box (SIEMENS LOA 24) checks the procedure.

A special nozzle draws the fuel, by using the passing compressed air, which serves as primary air for the combustion, and atomizes it. The combustion fan delivers secondary air that is mixed with the spray mist at the flame ring. Thereby a perfect combustion and safe operating are guaranteed.

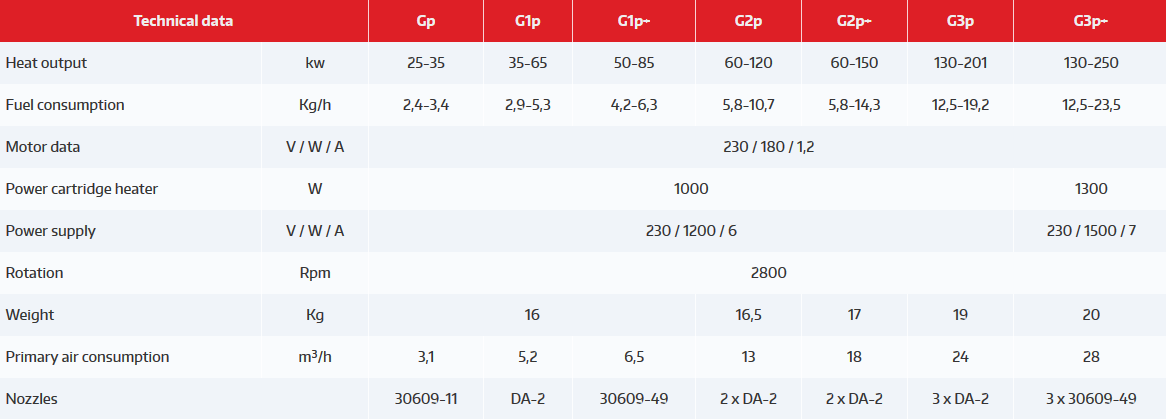

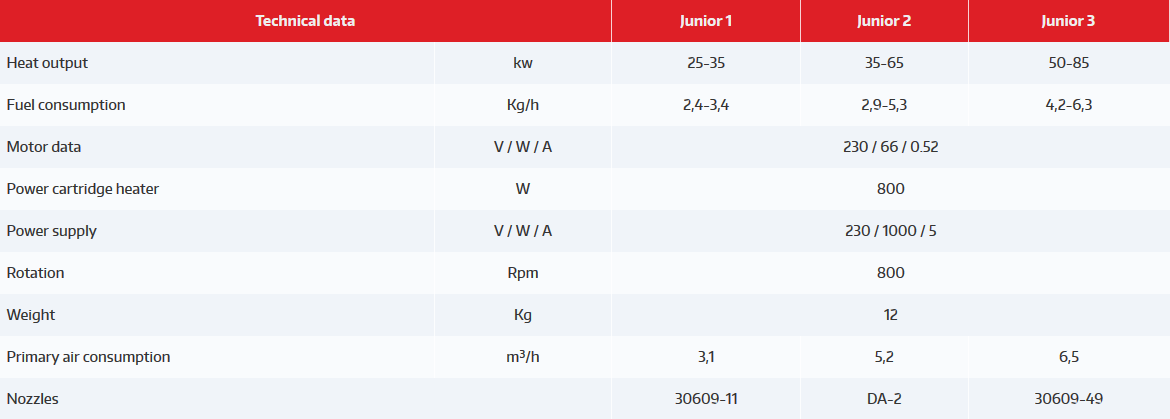

Tehničke karakteristike

GP Serija - Tehničke karakteristike

GP Junior Serija - Tehničke karakteristike

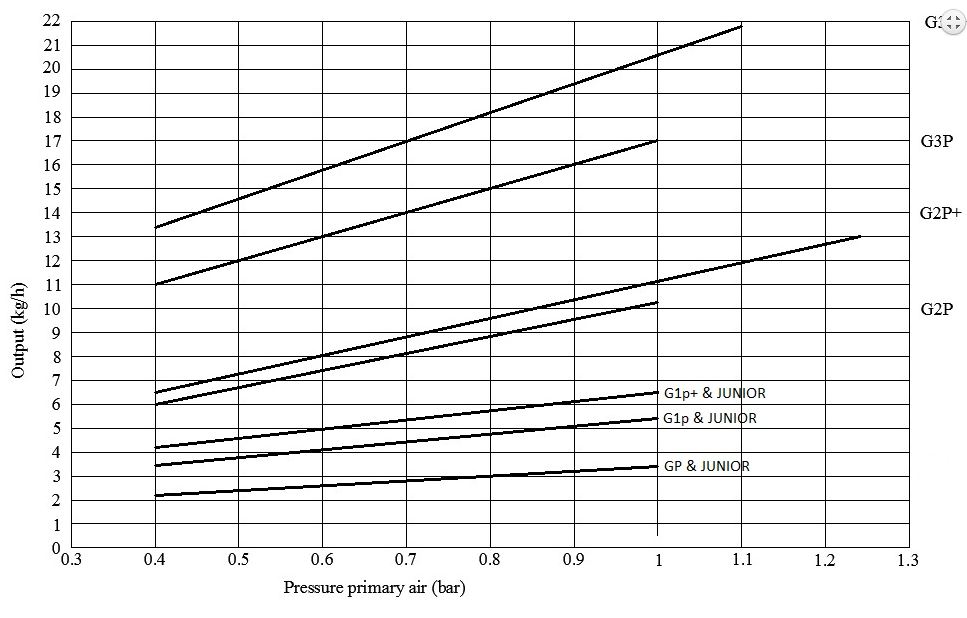

Heat Chart

Dimenzije

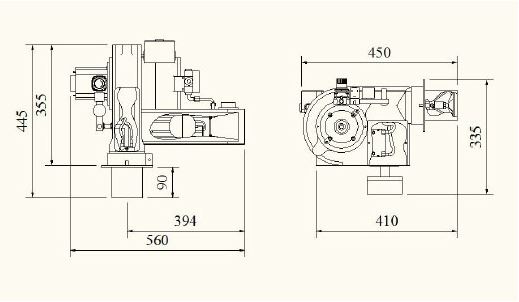

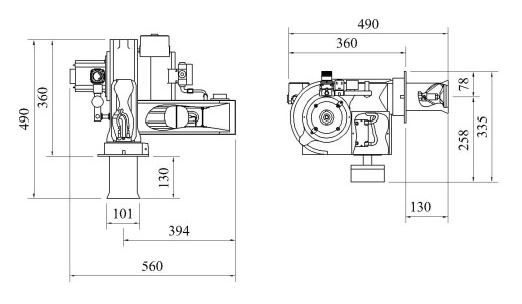

Dimenzije Gp & G1p

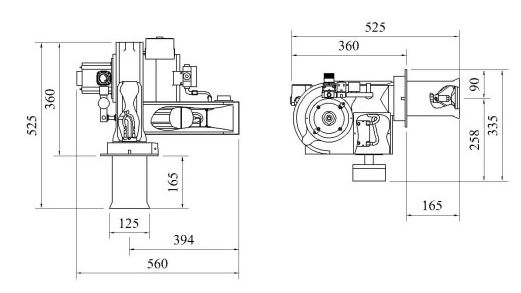

Dimenzije G3p & G3p+

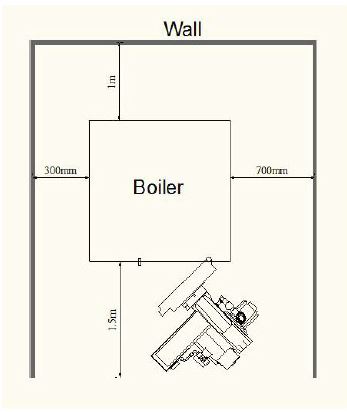

Lokacija Bojlera

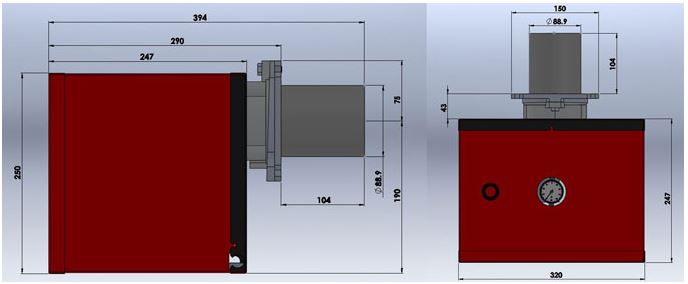

Dimenzije G2p & G2p+

Dimenzije Junior

Šema protoka ulja i vazduha

Opšte informacije

Multifuel burner must be installed in compliance with a number of regulations and requirements. It is therefore the duty of the installer to be familiar with all applicable regulations and requirements. Installation, start-up and maintenance must be performed with care.

Before installing CITERM Multifuel burner, please check the items supplied for completeness.

Scope of supply:

G-Series: Burner, mounting flange, flange seal, 7-th pole connector (plug), 8 meters of flexible oil line, Filter (optional )

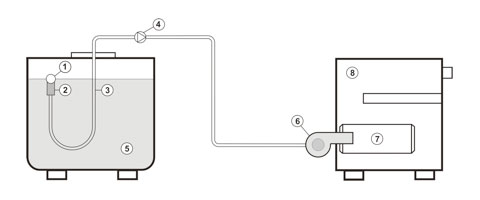

Junior: Burner, mounting flange, flange seal, 7-th pole connector (plug), 5 meters of flexible oil Line, remote pump with flex oil line and suction floater and strainer

Functional description

The combustible is pumped from the storage tank by a Inbuilt pump ( remote pump-JUNIOR ) into the burner tank. A double floating switch regulates the level in the burner tank and turn off burner in case of overfilling.

Float switch in overflow tank stops the burner in case of spilling oil in the overflow tank. A thermostat regulates the oil temperature in the burner tank and switches on the burner automatically as soon as the regulated temperature is reached. An additional overheat thermostat prevents overheating. A special nozzle draws the fuel, by using the passing compressed air, which serves as primary air for the combustion, and atomizes it.

The combustion fan delivers the secondary air that is mixed with the spray mist at the flame ring. Thereby a perfect combustion and safe operating are guaranteed.

SIEMENS LOA 24 control box control all parts and monitor the flame by photo–cell.

COMPRESSED AIR

The minimum supply pressure of 1,5 bar might be controlled by a air pressure regulator.

Fuels

- Floater

- Strainer

- Flexible oil line

- Remote pump

- Oil in the storage tank

- Burner

- Combustion chamber

- Boiler

The universal oil burners are suitable for use with a variety of natural oils, mineral based oils and synthetic oils. On account of their viscosity, these oils are not in conformity with EN 267 for oil burners. The burners are, therefore, not licensable. An inspection to determine suitability for the selected fuel type must be performed by the operator prior to acceptance of the installation.The design and degree of protection of the burner make it suitable for operation in enclosed rooms. When using synthetic oil – min. Mix it with 10% heating oil for start safety.

When use oil from plants – set oil temperature to „max“, because flash point is high.

When using heating oil EL – set oil temperature to „min“.

Conformity declaration

We declare, that the ventilated oil burners Gp, G1p, G2p, G2p+, G3p correspond to the basic demand of following directives:

Low tension directive

acoording 73/23/EC in connection with VDE 0700 partie 1 / version 04.88 and DIN VDE 0722 / version 04.83

Electromagnetic compatibility

according to directive 89/336/EC in connection with EN 55014 / version 04.93 and EN 50082-1 / version 01.92

Machines directive according directive 98 / 73 / EC

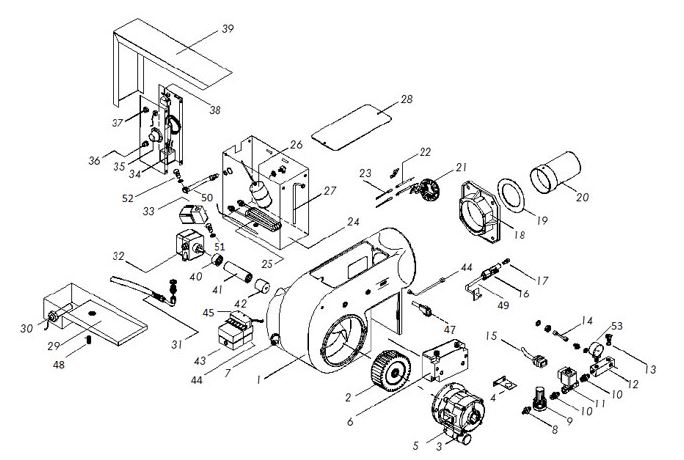

Glavni Delovi

Full Part List

- Burner body

- Fan wheel

- Condenser

- Air pressure regulator holder

- Motor

- HT Transformer

- Secondary air regulator (damper)

- Compressed air plug-in fitting

- Air pressure regulator

- Nipple ¼- ¼

- Solenoid valve air

- Air distributor

- 1/8 closing nut

- 1/8 – 1/8 male-female fitting

- Solenoid valve connector

- Nozzle head

- Nozzle

- Burner flange

- Flange gasket

- Flame tube

- Flame ring

- Ignition electrode

- HT cable

- Burner tank

- Heating cartridge

- Floater

- Copper pipe 1

- Burner body lid

- Overflow tank

- Contact switch

- Oil pipe

- Oil pump

- Solenoid valve oil

- Relay

- Regulating thermostat

- Safety thermostat

- Green light

- Double adjustable switch

- Tank lid

- Plastic coupling 8mm

- Rubber coupling 130mm

- Plastic coupling 12,7mm

- Control box

- Base for control box

- Socket 7-th pole

- Plug 7-th pole

- Photo cell

- Drain tab

- Pipe L-90 ¼ -1/8

- Oil pipe O1/4 – 1/8

- Nipple 1/8 -1/4

- Hollow screw ¼

- Pressure gauge